Servo Motor

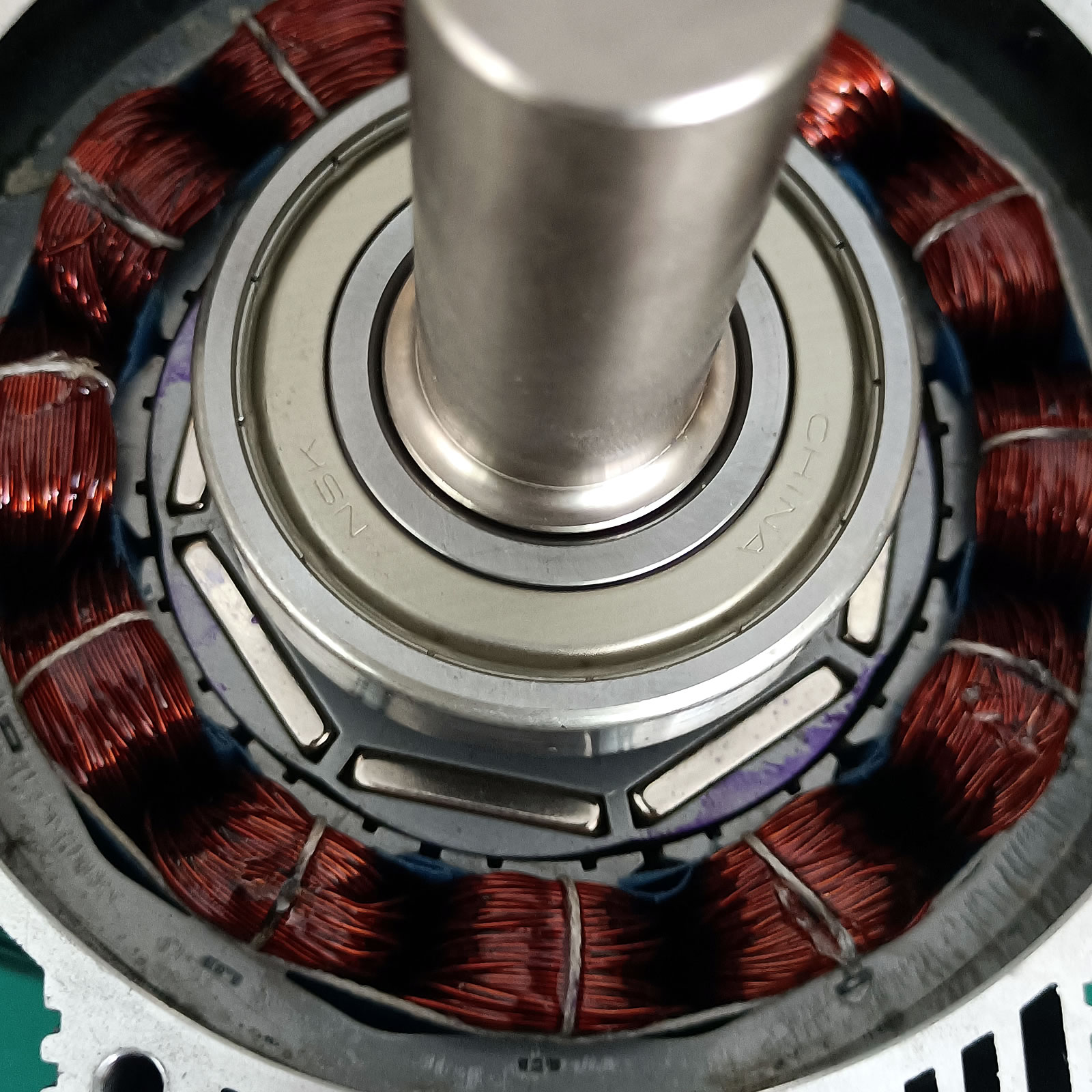

Joyance servo motor’s coil frame and enameled wire are all made of high-temperature resistant materials.

We use SH-grade magnets, which have a higher temperature resistance compared to H and M grades.

This makes our motor less prone to demagnetization and more durable.

The motor’s demagnetization temperature is high, it will not demagnetize as long as the internal temperature is below 150 degrees Celsius and the surface temperature is below 100 degrees Celsius.

The motor’s lead wires are capable of withstanding high temperatures up to 200 degrees Celsius, while other manufacturers’ wires can only handle temperatures ranging from 105 to 150 degrees Celsius.

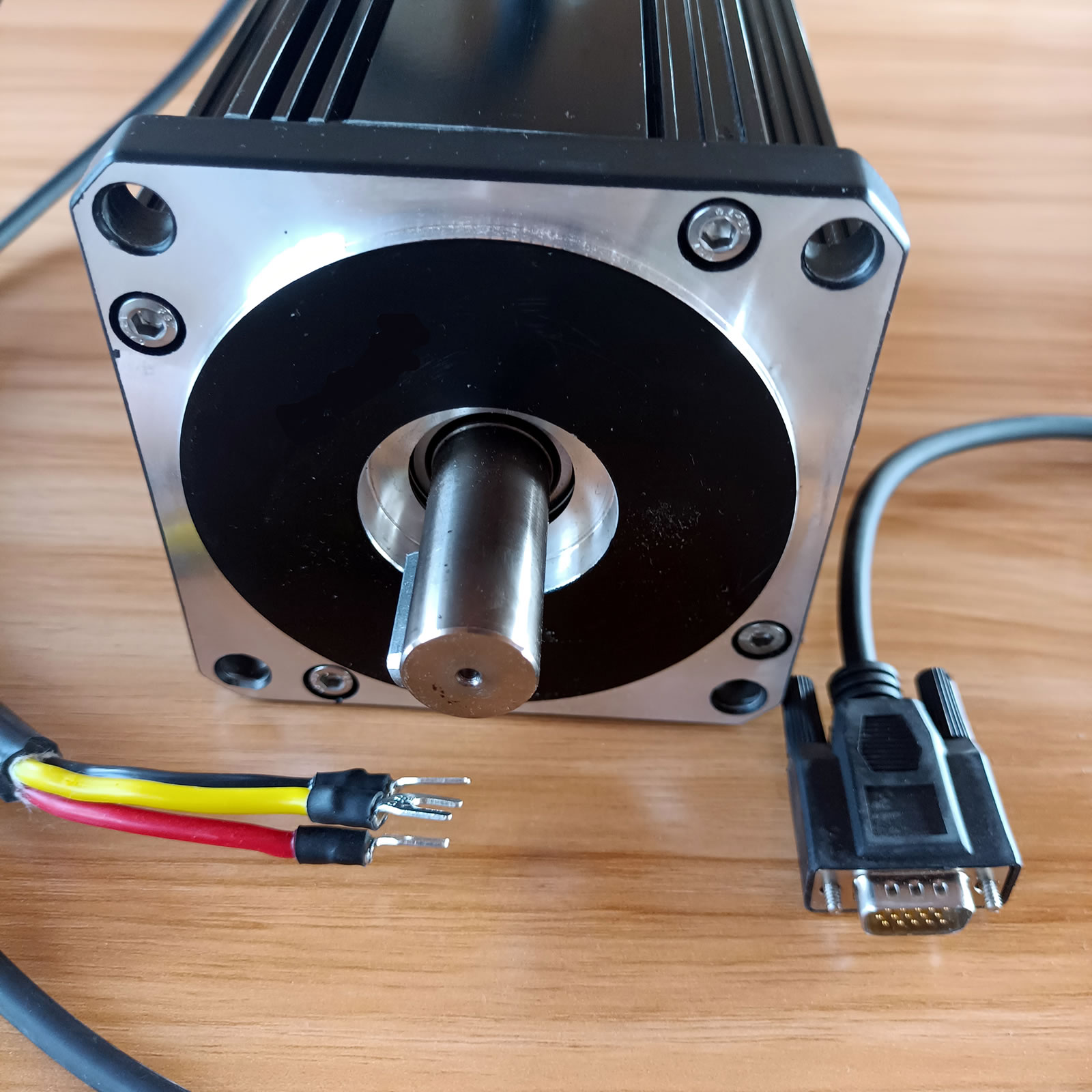

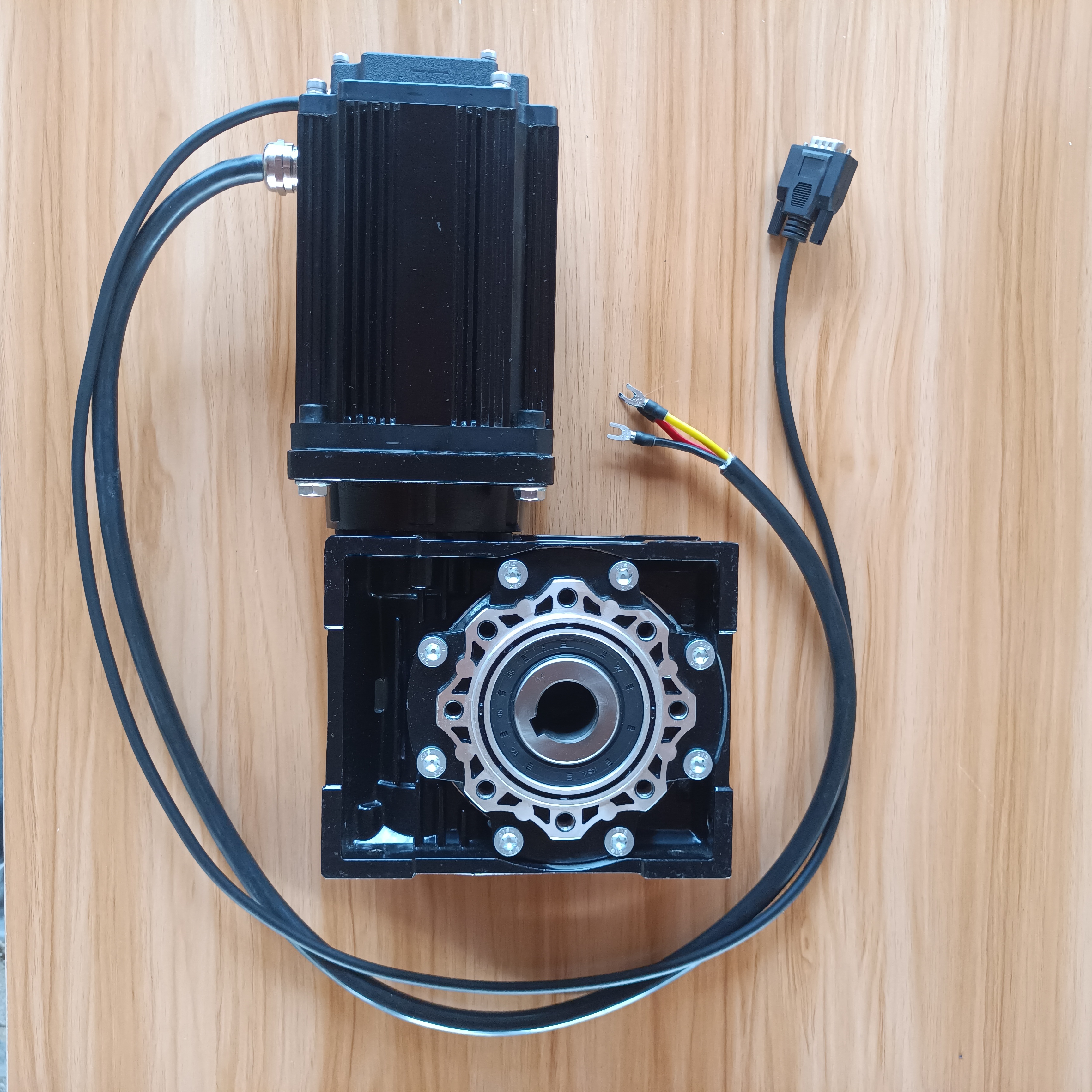

The power line (48V) and encoder line (5V) are separated to avoid the risk of the encoder being affected by high voltage breakdown.

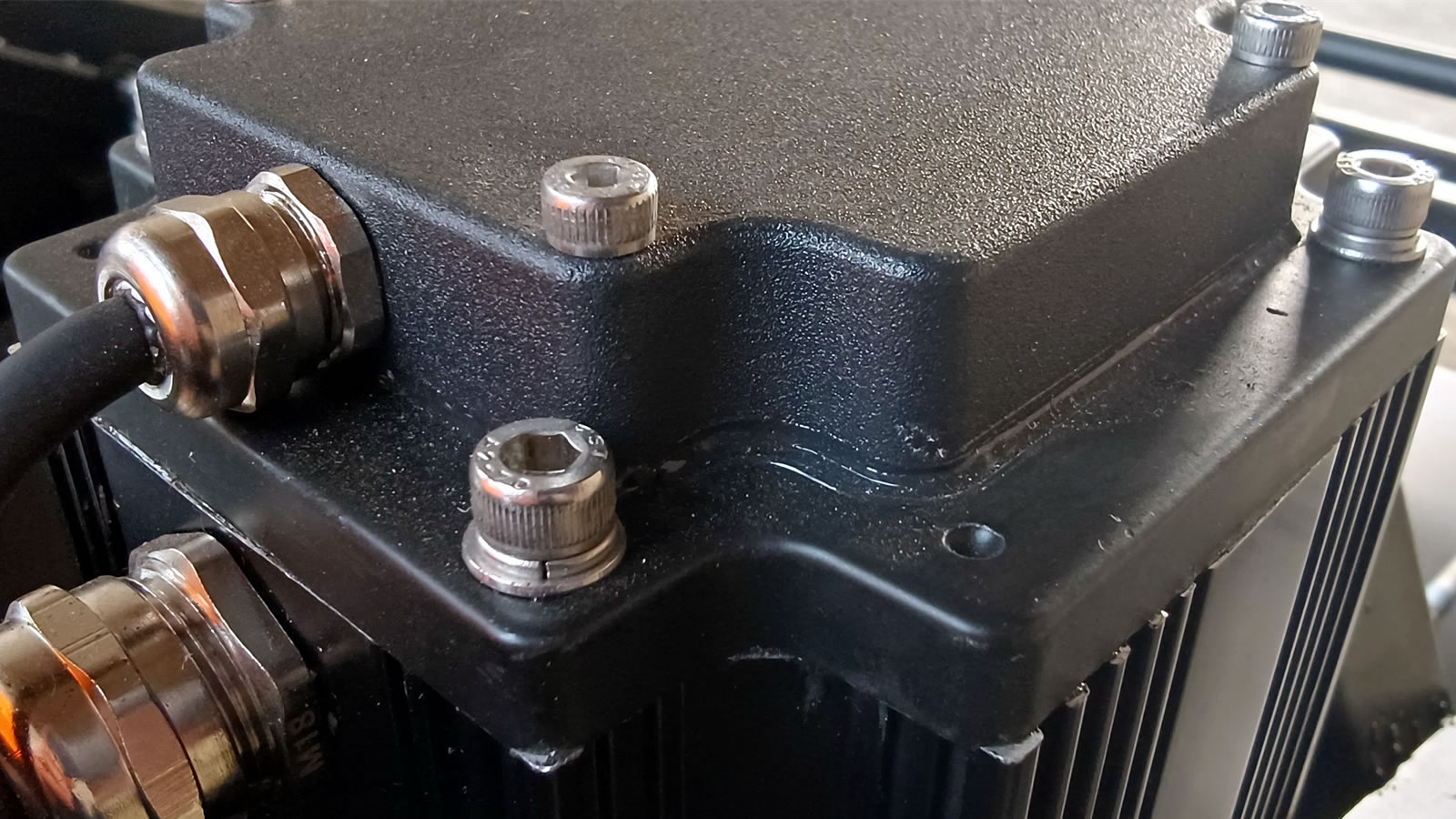

It is inevitable that lawn mowing operations will occur in the early morning when there is still dew on the grass blades, or in summer when there is high temperature and humidity, or when there is light rain during mowing.

Our motors are waterproof and specially sealed.

Our motor utilizes 42SH-grade magnets, which are two levels higher than most motors on the market that usually use 35, 38, or 40 grade magnets.

This enables our motor to generate stronger magnetic force, deliver higher torque, and withstand longer overload periods.

Comparing with a 35SH-grade magnet, the 42SH magnet provides a 15% increase in torque according to tests conducted on a dynamometer.

Our motor offers a maximum torque of 4.7N.m.

We use top quality imported NSK bearings, providing smooth and stable performance.

Furthermore, our brushless motor has an integrated encoder with 3 channels and 2500 lines, which is more advanced than a regular Hall sensor.

Ensuring smooth and stable operation even at low speeds.

The encoder allows for more advanced control, enabling faster and more accurate motor responses.

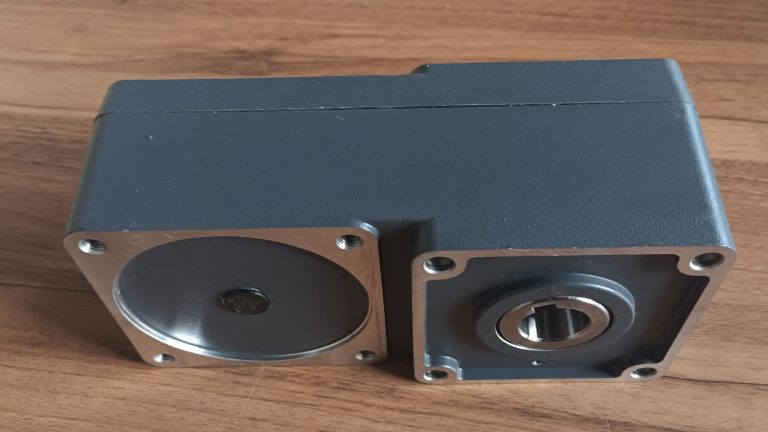

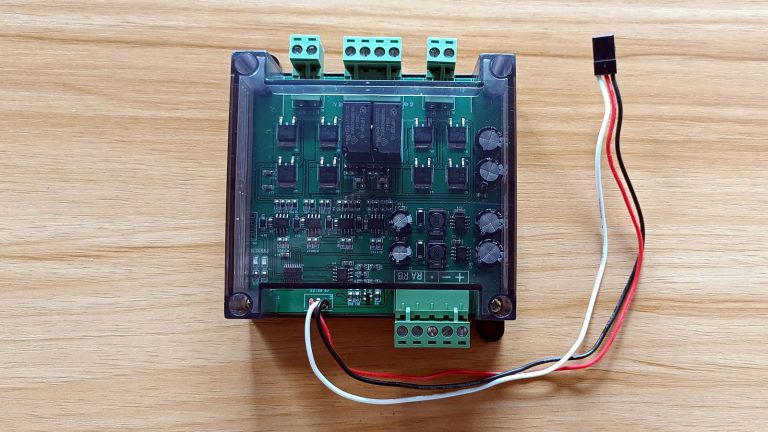

The matching servo motor driver has encoder control and comes with electric braking and axle lock functions.

It ensures that the motor remains stationary on slopes without slipping.

The high-voltage area of the controller is isolated from the low-voltage encoder area to prevent the encoder from being affected by high voltage breakdown.

Overall, our motor utilizes high-quality materials and components, providing enhanced performance, durability, and control precision.

Note: Please contact our sales representative to confirm which model of lawn mower this part is used on.